Contact Us

Address: 2424 Room 2424, Building 1, No. 1 Yile Road, Songshan Lake Park, Dongguan City, Guangdong Province

Tel:+8615602453032

Email:info@anti-sk.com

ESD products

- ESD Mat

- ESD Magazine Rack

- ESD Tape

- ESD Packing

- Pink Anti-static PE Tubing

- ESD Static Shielding Bag

- ESD Pink PE Bag

- ESD Circulation Rack

- ESD Tweezer

- ESD Brush

- ESD Stationery

- ESD Safe Bottles

- Wafer Spacer

- ESD Waste Bin

- ESD Trash Can Liners

- Earth bonding Plug

- Anti-static Velcro Straps

- ESD Plastic Pallet

- ESD SMT PCB Trolley Cart

- ESD Fabric

- ESD Wrist Strap

- ESD Heel Strap

- Ground Lead Kit

- ESD Component Box

- ESD Circulating Box

- Conductive ESD Anti-Static Tray

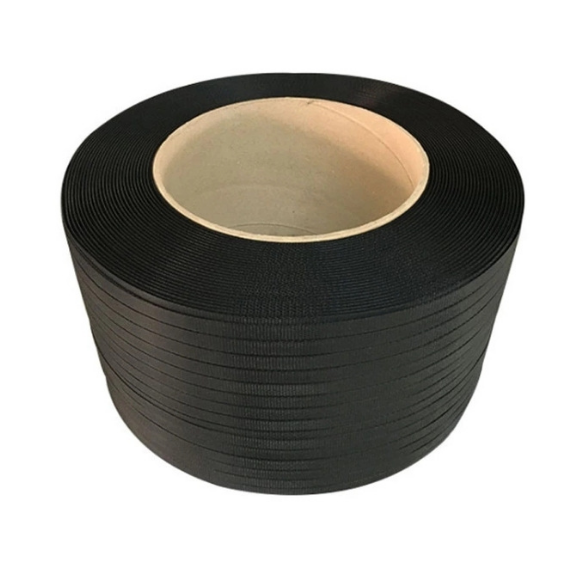

- Conductive/Antistatic PP Straps

- Silicon Gel Desiccant

- Heavy-duty ESD Workbench

- ESD Workbench

- Aluminum Alloy Anti-static Workbench

- Black IPXE ESD Foam

- Antistatic container or component box

- ESD Corrugated Box

- ESD Cleaning Mop

- ESD PU Foam

- EVA ESD Foam

Cleanroom products

- Cleanroom Swabs

- Cleanroom Finger Cot

- Cleanroom Wiper

- Cleanroom Shoes

- ESD Curtain

- Cleanroom ESD Glove

- ESD Cleanroom Garment

- ESD Cleanroom Chair

- ESD Castor

- Cleanroom Cap

- ESD Clean room Sleeve

- ESD Cleanroom Bag

- Cleanroom Sticky Mat

- Silicon Sticky Mat

- SMT Stencil Roll

- Cleanroom Sticky Paper

- Disposable Non-woven Products

- ESD VACUUM CLEANER

- Cleanroom Notebook

- Cleanroom Paper